Otter DTF Technical Support

Preparatory work

1. How to properly install a roll of film?

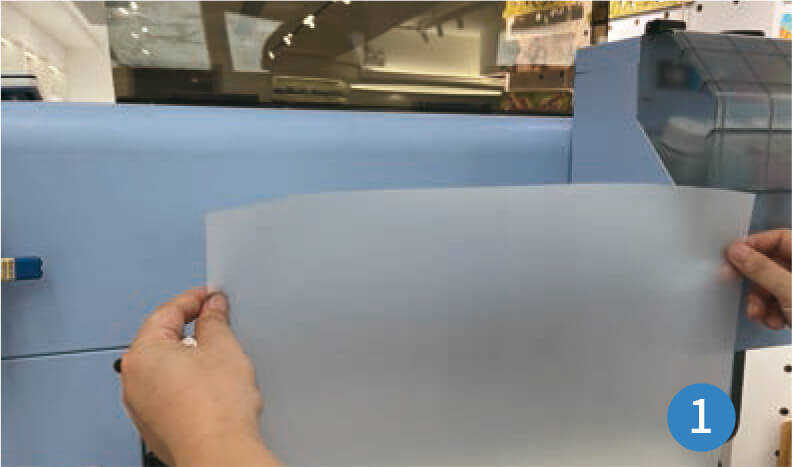

For beginners, it is important to learn and pay attention to a few tips when installing film on a DTF printer. Incorrect installation can lead to printhead damage

First, make sure that the printable side of the film is facing outward.

Place the rod in the core of the film roll.

Adjust the tension with the smooth feed cushioning mechanism.

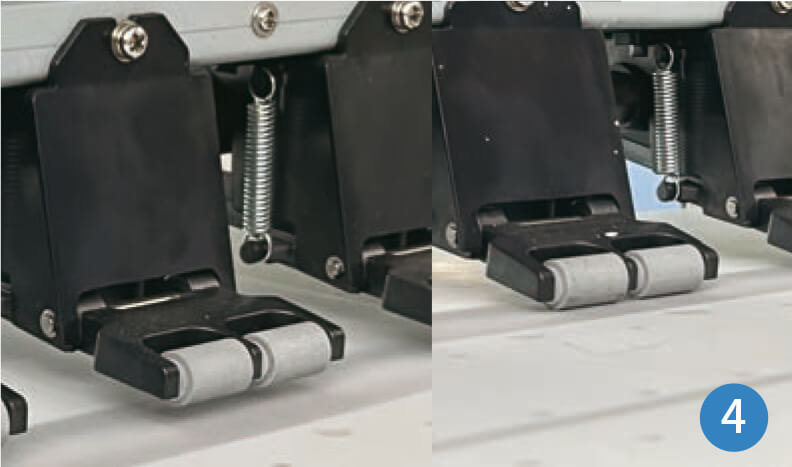

Make sure the pressure roller is set to press both sides of the film, then lower it to the position.

Finally, use the guides to position both sides in the correct place.

2. When to refill ink and how to do it?

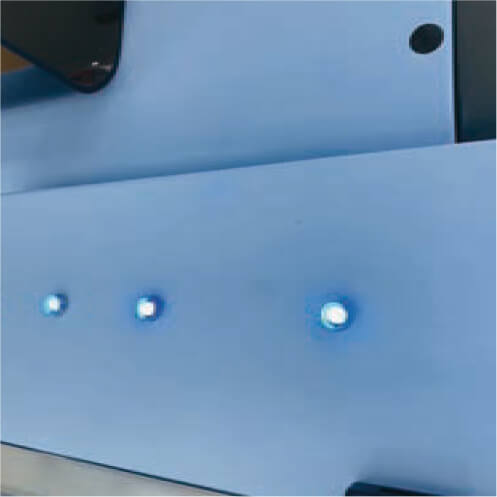

If the ink level is low, the blue light above the corresponding ink tank flashes and beeps. In this case, refill the ink

Note which ink tank is low and refill it with the appropriate color.

Unscrew the cap and refill the ink until the beep stops indicating that the ink refill is complete.

No need to turn off printer while adding ink. Even while printing, you can add ink without affecting print quality

3. What to do after replacing the print head

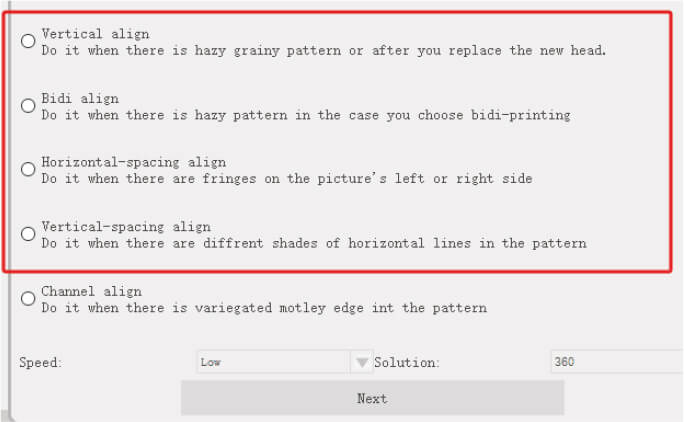

Replacing the print head on a DTF printer is a critical task, so be sure to read the manual for precise instructions. After replacement, calibrate the print head to ensure smooth and successful printing operations

If the lines are still not aligned, repeat this step until they are aligned.

In the same way, align the position of the white nozzle.

Otter DTF printer maintenance

Regular maintenance is critical for DTF printers to maintain optimal performance. This practice not only extends the life of the printer and heads, but also guarantees the quality of the prints and finished products.

Daily maintenance

Maintenance of print head nozzles

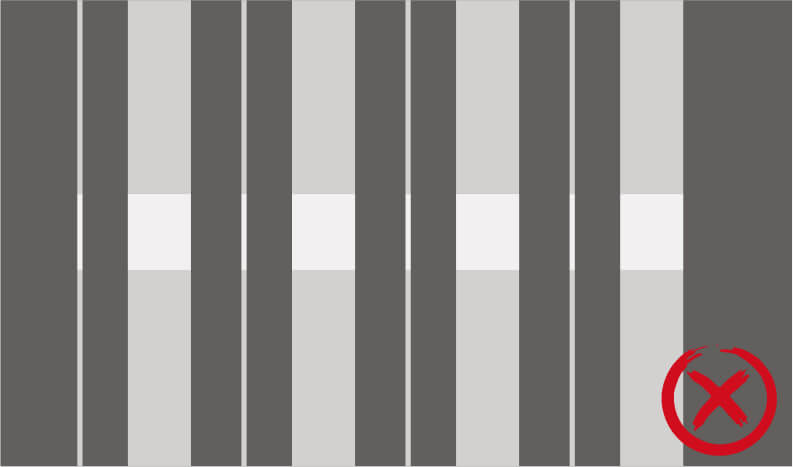

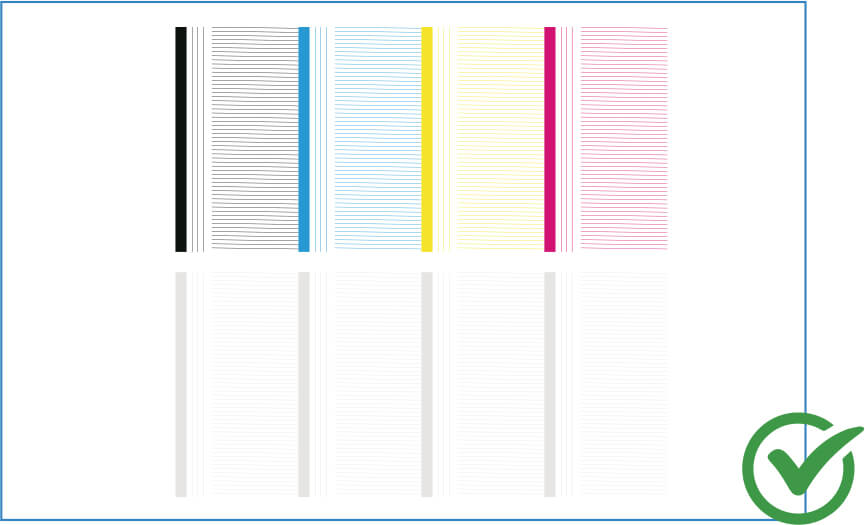

After turning on the printer, conduct a nozzle test. After printing the test pattern, check it carefully for missing or misaligned lines. Each line in the pattern corresponds to a specific nozzle on the printhead.

Solution: if all lines are present and uniform, the nozzles are working properly. However, if the lines are missing or irregular, this indicates nozzle clogging or misalignment. Perform the cleaning procedure again until the nozzle test is correct.

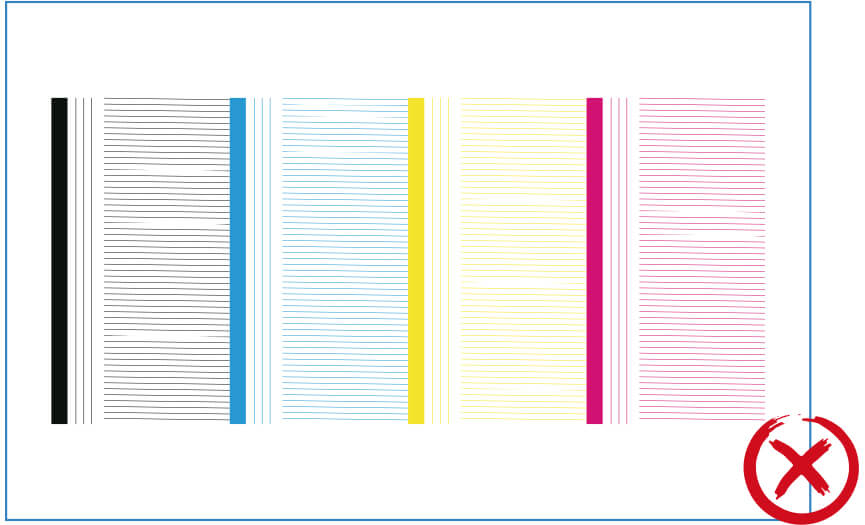

Platform maintenance

Make sure the printing platform is clean. If there is ink residue or dirt on the platform wipe it off with a lint-free cloth soaked in alcohol.

Do not place any foreign objects on the printing platform, as this may cause damage to the print head during printing or moving.

Weekly maintenance

Cleaning the encoder strip

If the encoder bar is not cleaned regularly, the printer may not read the printing area accurately, which may affect the quality of printing.

How to do it?

Wipe the dirt and dust off the encoder strip with a lint-free cloth soaked in alcohol.

Cleaning the guide rail

Keeping the guide rails clean is essential for maintaining precise printhead movement, which directly affects print quality.

How to do it?

Wipe off dust or dirt with a lint-free cloth and regularly apply a small amount of grease to the guides.

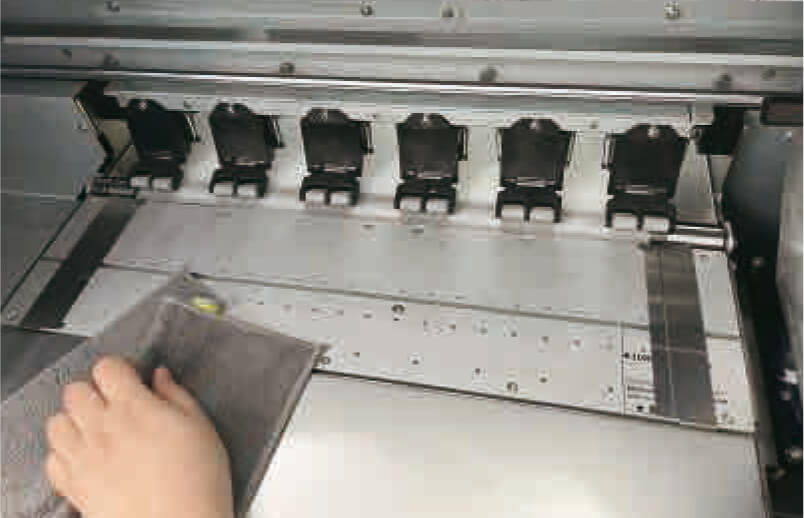

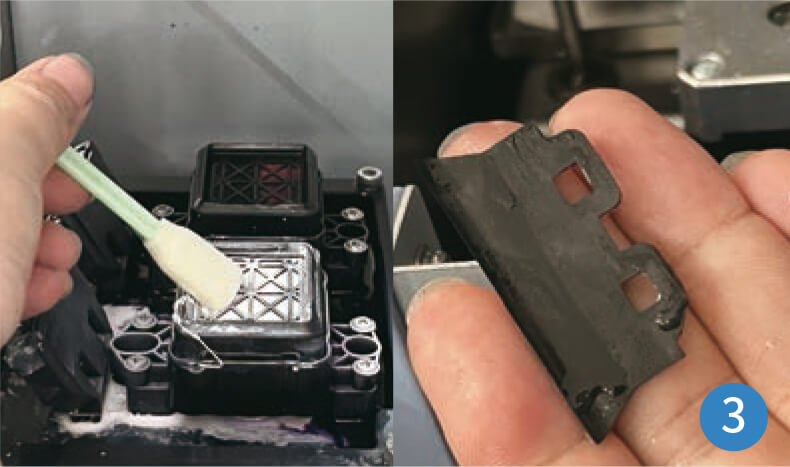

Cleaning the docking station

When the printer is not in use, the docking station closes the nozzle and keeps it moist, preventing solidification of the ink, which can cause nozzle clogging. Clean the docking station regularly.

How to do it?

Turn off the printer, wet a lint-free cloth or a thumbtack with a suitable solution to wipe off excess ink from the edges of the. Let it dry completely, then turn on the printer.

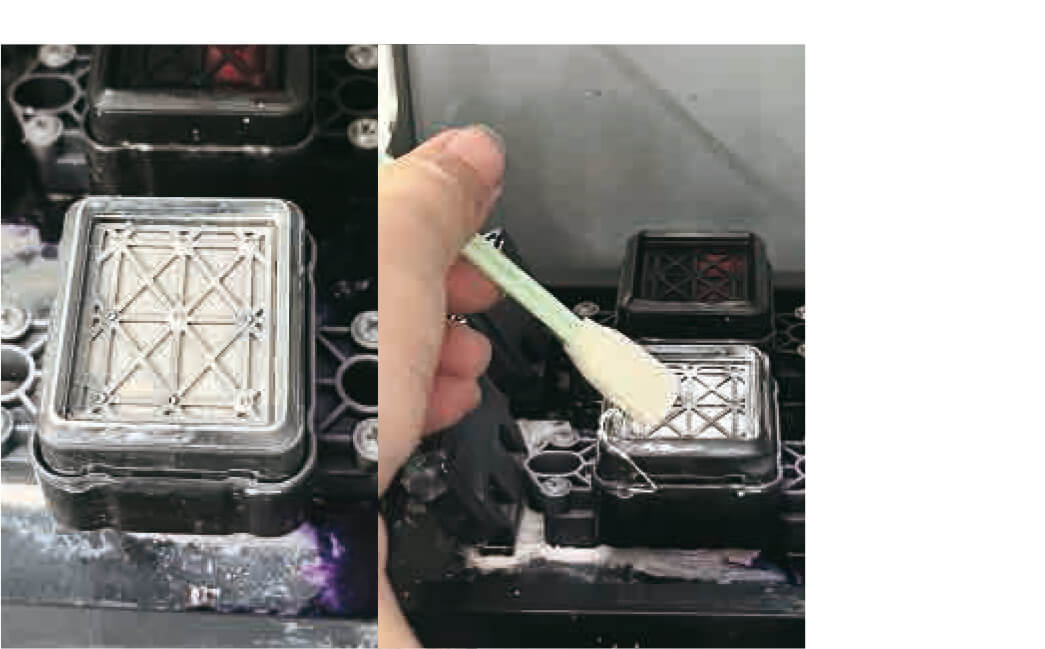

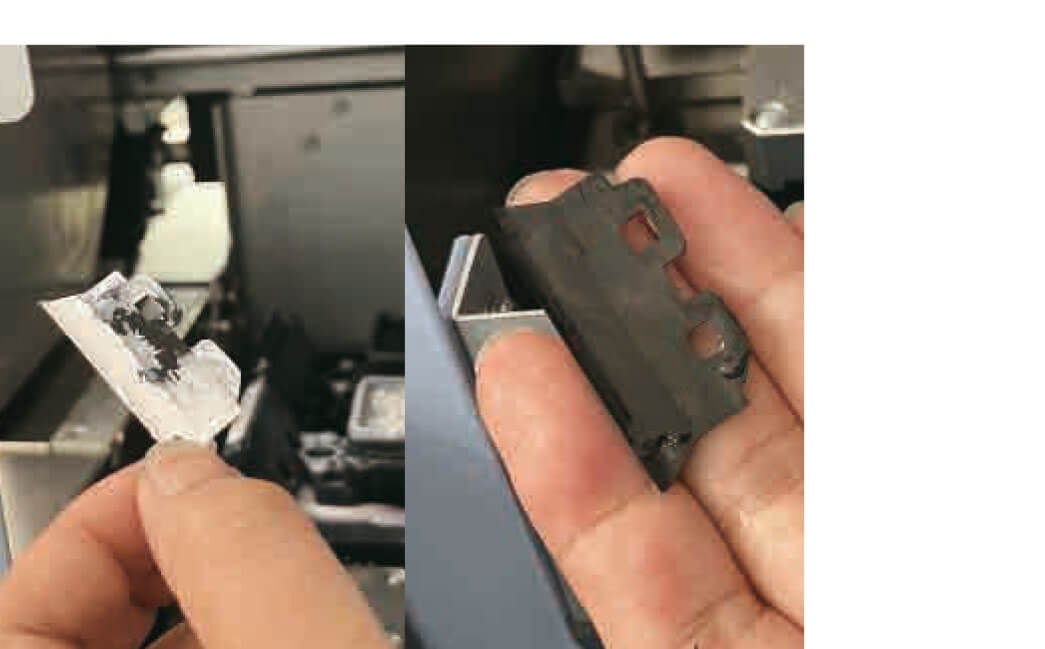

Wiper blade cleaning

The wiper blade is a component that removes excess ink or ink residue from the print head. Provides a steady flow of ink and prevents streaks in the printing process.

How to do it?

Turn off the printer and, using a lint-free cloth moistened with a suitable solution, gently wipe the wiper blade.

Attention:

- DTF printer should be operated by trained personnel and supervised throughout its operation.

- When printing, watch for ink and film shortages. When the ink level is low, the printer signals the need for a refill.

- Constantly monitor the flatness of the film and the condition of the print head to prevent print head scratches caused by film jamming.

- We recommend using the printer every day. In the absence of orders, we recommend printing a test area every day to prevent the head from drying up. Two days /e.g., weekend/ without printing will also maintain optimal printing levels.

REMEMBER

To maintain optimum printer performance and print quality, consider the effects of humidity and temperature.

The temperature in the room should be 25-28°C, and humidity levels 50-60%.

Place a temperature and humidity meter near the printer to closely monitor the printer's operating conditions.

Troubleshooting Guide - Software

Before running the Otter DTF printer, download these two programs.

1. Otter DTF Printer Mainboard Control Software - otter DTF printer motherboard control software - Otter DTF printer control (cleaning, maintenance and calibration.

2. Otter RIP Software - for image processing and color management.

1. What to do when software suddenly crashes?

If you find yourself in such a situation, contact our after-sales service team and we will provide you with a software upgrade.

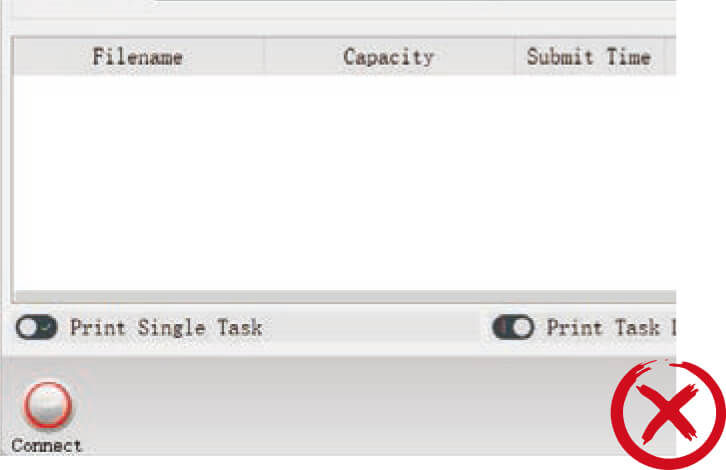

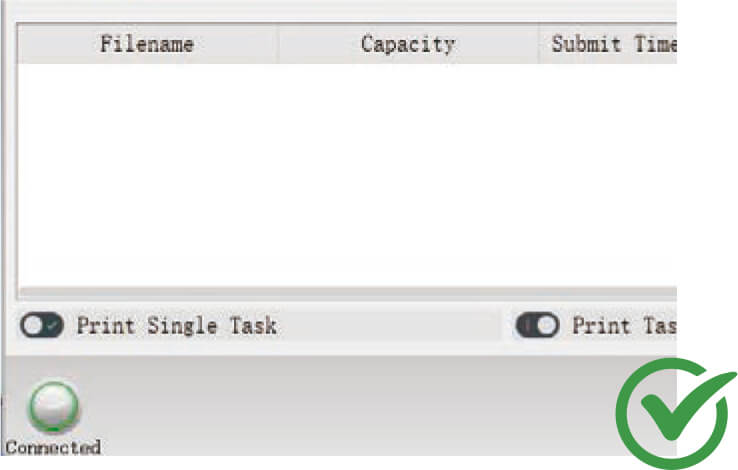

2. What to do when the printer does not respond to software operations?

Check for sudden power failures or network cable disconnections.

If the control software fails to connect to the computer, try restarting the printer and software.

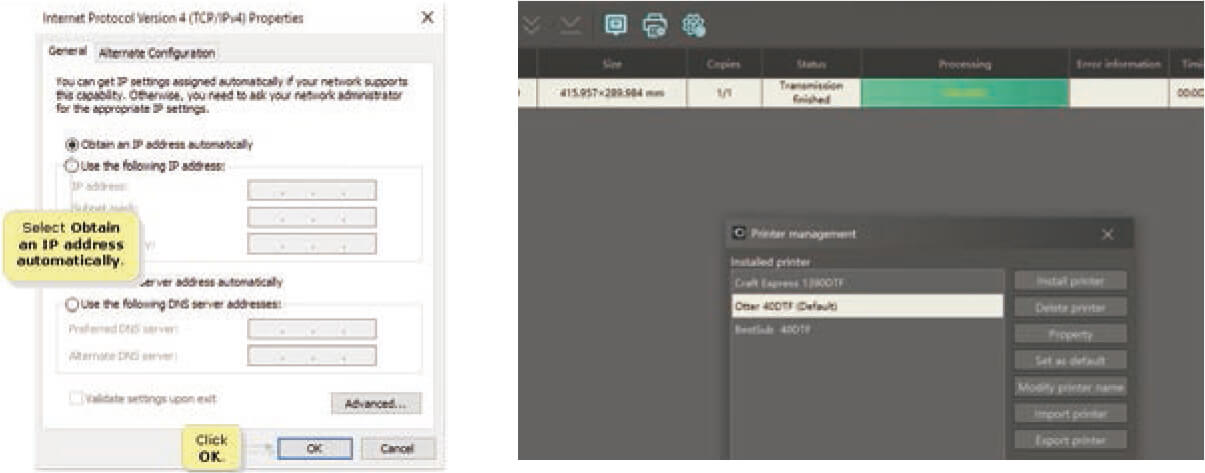

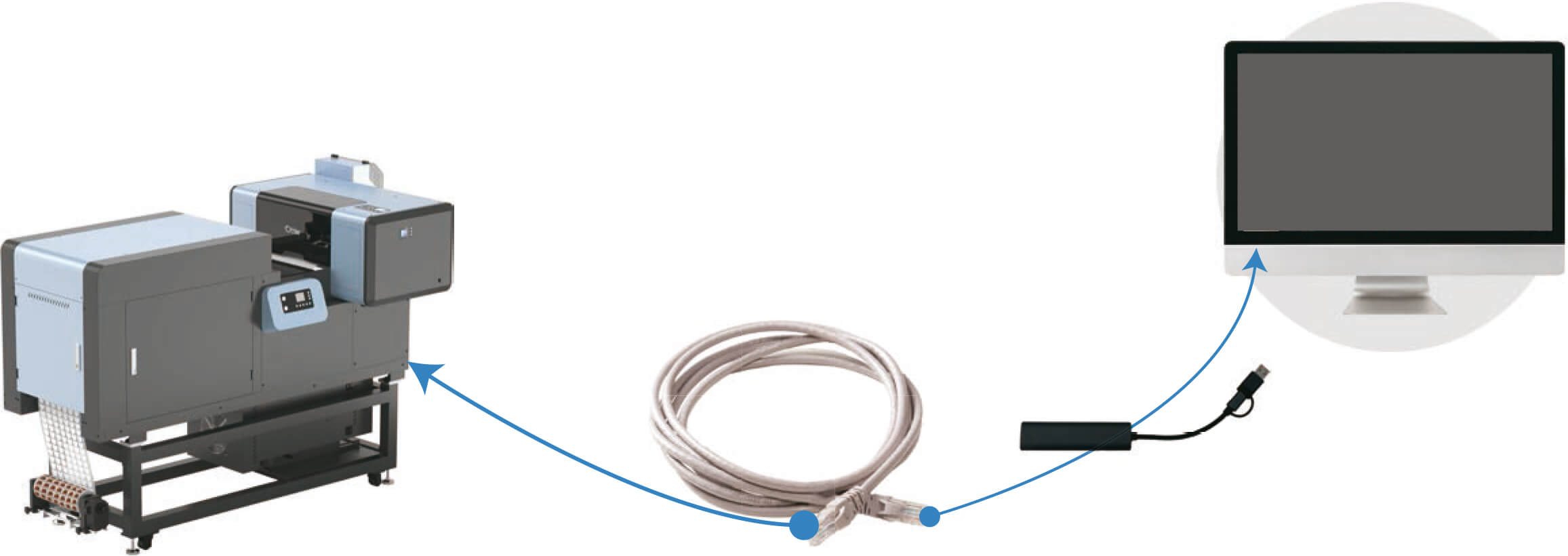

3. What to do when Otter RIP software fails to connect to printer when sending print data?

Solution 1

Check your computer's IP address and that it is set to automatically obtain. Then set the Otter DTF printer as the default printer.

Solution 2

Make sure you use a Gigabit Ethernet cable (included in the spare parts kit) to connect to your computer.

If your computer is not equipped with a Gigabit Ethernet port, use a Gigabit Ethernet adapter.

Troubleshooting guide - common problems with DTF printouts

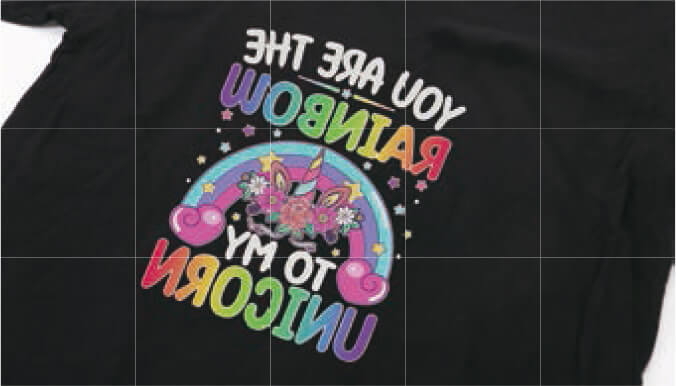

1. How to remove the white outline?

Check that the white line comes from the project.

If so, adjust the design in the software

Open the software (Otter DTF Mainboard Control Software) and perform the print head calibration indicated by the red box.

When finished, test again. If the problem persists, go to the next step.

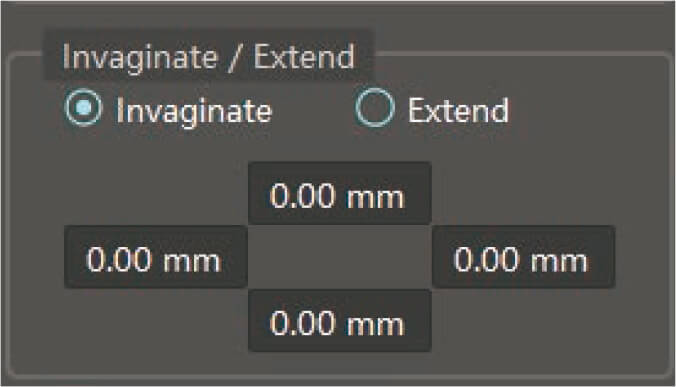

Open the software (Otter RIP Software) and click W1 and W2 on the right side, then select "Invaginate" and adjust the settings in the four fields or on the side where the white line is, making sure it is between 0.1-0.2 mm.

2. Why DTF powder sticks to the unprinted area of the film?

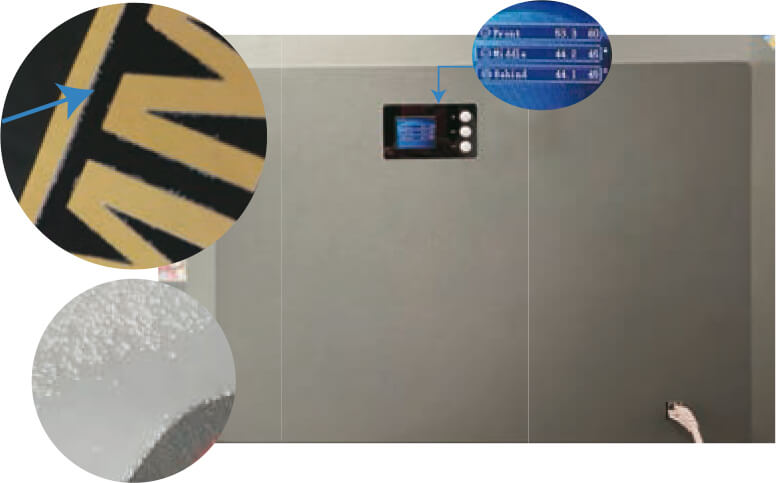

Adjust temperature settings on DTF printers. We suggest setting the temperature parameters to 60-45-45°C for optimal results. This will help eliminate excess moisture from the film.

Check the quality of DTF powder and replace it if it becomes clumped or wet.

In the Otter DTF Mainboard Control Software, set the printer's standard print speed. This will ensure that the film heats up evenly during printing, facilitates even powder distribution, and ensures a constant speed as you enter the baking tunnel.

3. How to prevent oil return on DTF film?

- Adjust the temperature settings on the printer's heating system to 60-45-45°C.

- Control the curing temperature. We suggest setting the temperature to 150°C for the dryer so that the powder dissolves completely. If you are using an Otter all-in-one DTF printer no adjustments are required.

- DTF film should be stored properly. Use the printed film immediately to prevent oil from returning due to improper storage. For storage, use an airtight container and store it in a cool, dry place away from direct sunlight. Try not to store the printed film for too long. It is best used within 2-3 days.

- If oil returns, dry the vial for 2-3 minutes.

4. How to prevent clogging of print heads?

Use high quality DTF ink. We recommend using OtterPro DTF ink, it is compatible with Otter DTF printer.

Clean printheads regularly to maintain optimal performance.

It is recommended to clean the print heads at least once a week.

Always test heads before each print. If printing results are not optimal, immediate cleaning is necessary.

Regularly clean the docking station and wiper blade. It is recommended to perform this activity every week to ensure smooth operation.

5. How to avoid white spots on printed film?

- Use high quality ink and make sure that the water content of the ink is within normal limits.

- Make sure the water has completely evaporated and the printed film is fully cured to avoid incomplete drying resulting in white spots.

6. When to replace the print head?

Printheads typically have a limited lifespan depending on how often the printer is used. For the average user, the heads last about 7-8 months.

If you regularly clean and calibrate the print head, but still observe a decrease in print quality, it may mean that the print head needs to be replaced.

Mechanical damage, such as scratches, is another sign that the print head may need to be replaced.

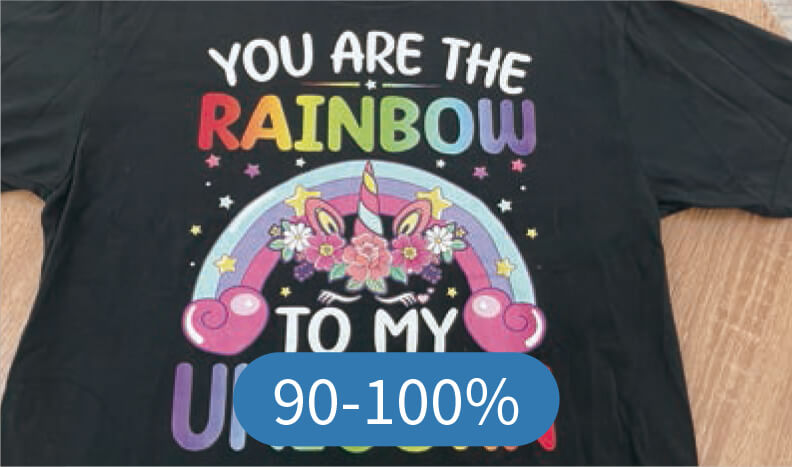

7. How to adjust the white ink ratio for different designs?

For bright designs, if the goal is to save white ink, we recommend setting the white ink ratio to 50%.

For dark patterns, setting it to 90-100% will give the best pattern effect.

8. How to prevent the edges of the printed pattern from warping after the transfer?

- choose the right fabrics. Softer fabrics may cause deformation of the pattern.

- Apply the right temperature and pressure to distribute heat evenly over the printed pattern, preventing warping of the edges.

- Make sure the fusible powder remains unaffected by moisture.

9. How to solve DTF printer problem with no white ink printing?

Check if the ink damper shows separation.

Try slightly loosening the cap of each ink bottle, clean the print head and check the nozzle before printing to make sure the test lines are complete.

10. What to do when printer's carriage hits left end and stops moving?

- Make sure there are no obstacles blocking the movement of the cart along its track.

- Wipe the dirt and dust off the encoder strip with a lint-free cloth soaked in alcohol.

- Apply a small amount of grease to the rail of the carriage to ensure smooth movement.

11. What to do when printing is suddenly interrupted?

If dropping stops suddenly without any error messages, and the print heads return to the initial position, do the following to solve the problem:

- Check that the USB connection is not loose or disconnected.

- Check if the computer is responsive. If not restart it.

- Check if your computer's C drive is full, as it may affect printing.

- Try printing from another computer to see if the problem persists.

- Make sure that the voltage supplying the printer is stable. Voltage fluctuations can cause interruptions.

The above steps can help you diagnose and resolve sudden interruptions in the printing process.

12. What to do when there are color differences in printed patterns?

- First, perform a print head test. This will help identify any color defects in the prints.

- If the color on the test strip is incorrect, clean the nozzles.

After cleaning, re-enter the nozzle test to make sure each color is correct.

Attention: it is important to perform a print head test before printing any designs. This ensures that the print heads are in optimal condition, which will help prevent color discrepancies in printed patterns.

If a shadow is visible on the printed patterns, clean the encoder strip with a lint-free cloth soaked in alcohol.

13. What to do when color is not visible despite cleaning the print head?

Usually, this problem is due to excess used ink on the cover and wiper blade, which can lead to clogging of the head nozzle.

Attention: regular cleaning of the wiper cover and wiper blade is an essential activity to keep the printing flowing.