Otter DTF 60 multifunctional system

- Otter DTF 60 multifunctional system

Product description

NOTE: We price transport individually for this.

The maximum print size of this large format printer is 60 cm/23.6 inches, equipped with two advanced Epson i3200 print heads, this printer provides faster and more accurate prints. It is ideal for printing on larger garments, jeans, advertising fabrics, as well as for mass production of custom garments and larger scale projects.

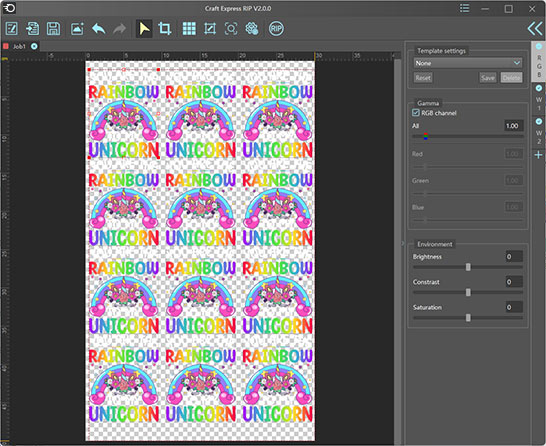

Software included Otter RIP. This software significantly increases the productivity of DTF printing projects! It has a simple but powerful interface, allowing you to effortlessly master image editing and design. What's more, it supports automatic layout of multiple images and duplicate printing, which greatly increases productivity. Superior color printing ensures that DTF printers achieve "what you see" results.

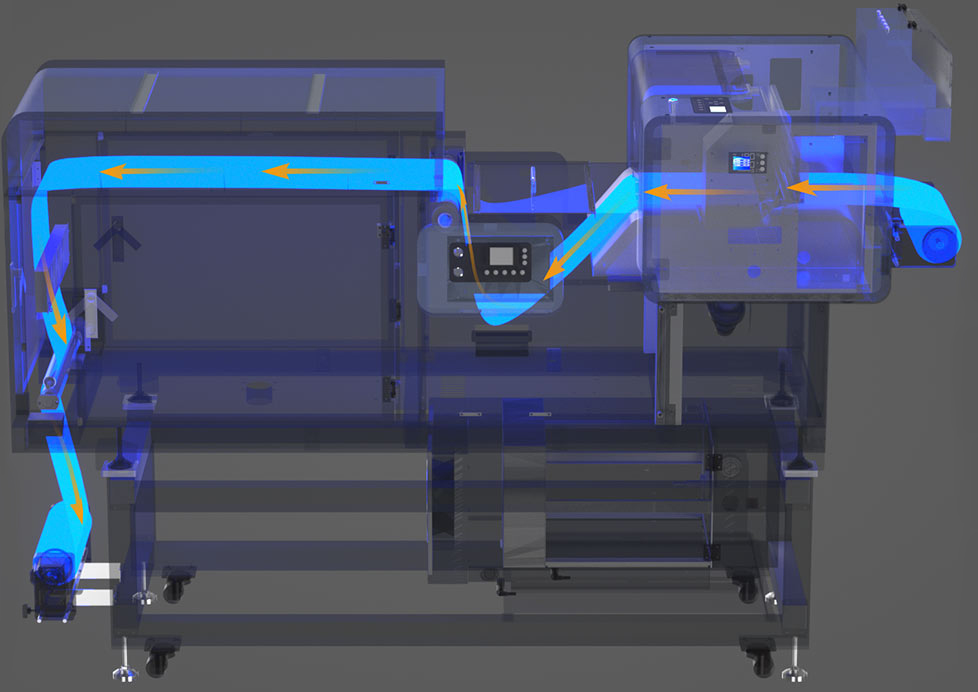

Integrated automated DTF system

Equipped with sensors, the system allows one-touch control for automatic printing and even shaking and drying of powder, as well as film winding.

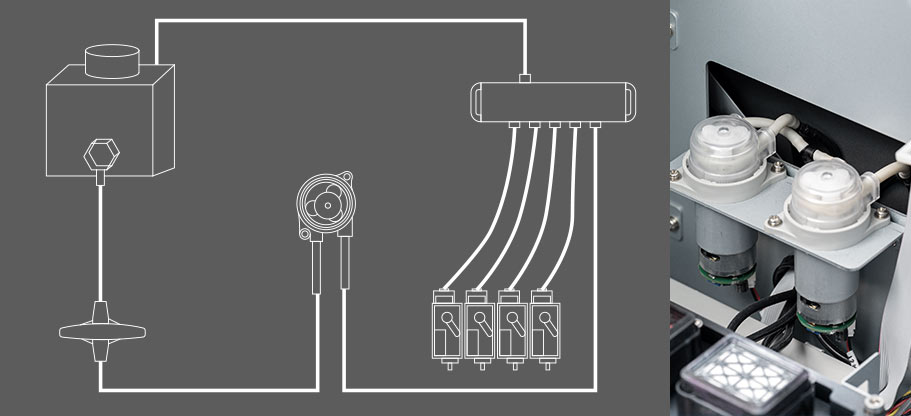

Automatic circulation of white ink

Built-in peristaltic pump with moderate pressure and good gas seal protects the print head. Continuous circulation of white ink effectively prevents ink buildup and reduces the likelihood of printhead clogging.

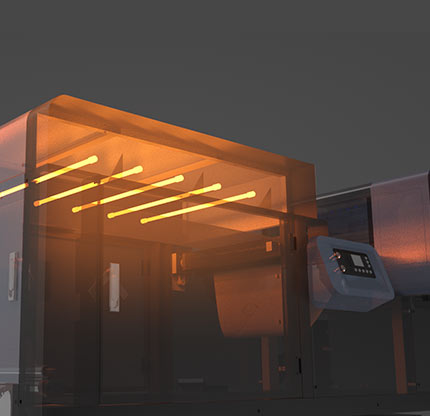

Drying system

Equipped with five heating tubes and a larger drying area, the drying system provides even heating of the print for excellent results.

Receiving spool system

With the automatic winding system, you can free your hands at the final stage of production, achieving intelligent and safe film winding.

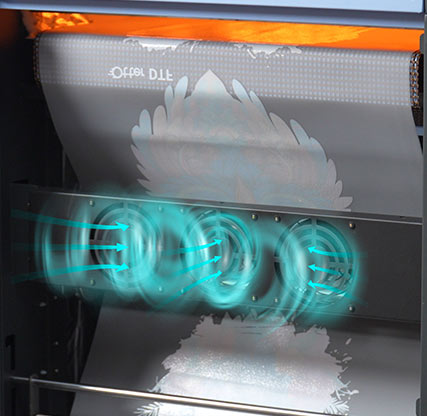

Built-in fans

After the printed film is burned in the oven, built-in fans speed up film cooling and improve productivity.

Printing width

With a maximum print width of 44.8 cm, the system is compatible with standard film widths available on the market, including 30 cm, 33 cm, 42 cm.

Powder shaking system

Can effectively improve melt powder utilization rate and minimize waste. In addition, it avoids the hassle of shaking the powder by hand, so the powder can be more evenly distributed on the film.

Control panel

User-friendly control panel allows you to manage speed, power and temperature of powder and drying system, providing a clearer picture of printing status.

Integrated purifier

Air purification system can automatically clean smoke and oil, improving well-being and productivity. (There is no need to change the cotton filter)

Three-stage heating system

Accelerate DTF ink drying on film to guarantee optimal image quality before powder application.

THK Mute Linear Guides

Increased operational stability with minimal noise.

Ink supply system

Clear ink markings avoid the hassle of pouring the wrong ink. Built-in alarm sensor reminds you to add ink on time, minimizing printer damage.

Otter RIP Software

Automatic system

Color consistency

High performance

Excellent color accuracy

This software significantly increases the productivity of DTF printing projects! It has a simple but powerful interface, allowing you to effortlessly master image editing and design. What's more, it supports automatic layout of multiple images and duplicate printing, which greatly increases productivity. Superior color printing ensures that DTF printers achieve "what you see" results!

| Head: | EPSON i3200-A1 - 2 pcs. |

| Color: | H1: CMYK / H2: W |

| Print speed: | 5,5 m2/h |

| Print width: | 0-600 mm |

| Power: | 3300 W ± 5% |

| Powder container: | 1 kg |

| Automatic white ink blending: | yes |

| Pressure roller: | front and rear manual control |

| Computer connection: | gigabit Ethernet port |

| Printer cart: | without anti-collision system |

| Sensors: | low ink level no film |

| Heating system: | independent three-stage heating |

| Supported files: | .bmp, .jpg, .png, .tiff, .pdf |

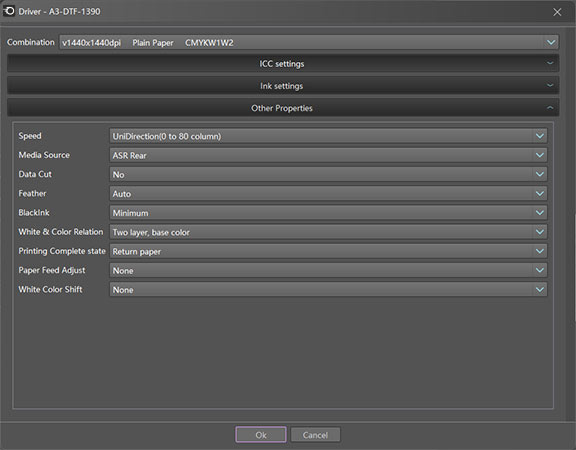

| Print Mode: | unidirectional / bi-directional |

Otter DTF Product Warranty

The warranty document in PDF format is available for download here.