Operation of the Virtuoso VJ628 printer

getting started

See the start-up guide movie to learn how to unpack and set-up the new Virtuoso VJ628 printer.

basic operations

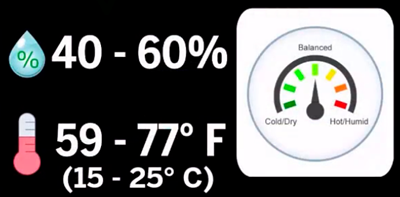

Before and during printer’s operation it is necessary to control temperature and humidity. This ensures proper functioning of the printer and high quality of prints.

Depending on the working load it is necessary to check the paper cutting blade once every 6 months or 1440 working hours.

Inspection should include jagged cut edges or if paper dust begins to collect around cutting areas and capping station.

Replace as needed with:

cutter blade - RPRT99VJCB.

During daily operation it is necessary to check the holders for bent edges, abnormal wear or if ink and paper dust collects underneath.

Before printing slide back and forth to clean area underneath.

Nie należy używać drukarki, jeśli uchwyty są wygięte, ponieważ może dojść do uderzenia głowicą, co może być przyczyna jej uszkodzenia.

Do not use printer if holders are bent as headstrike may result:

media holder assembly - RPRT994697.

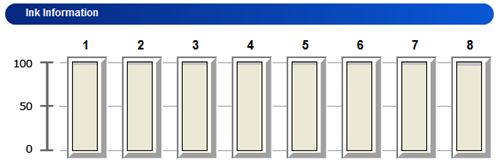

At the beginning of each production cycle it is necessary to check ink cartridge level. It is worth to plan purchase of new ink cartage ahead to avoid its depletion during printing.

Ink level can be checked on the ValueJet Status Monitor.

Learn how to use the ValueJet Status Monitor

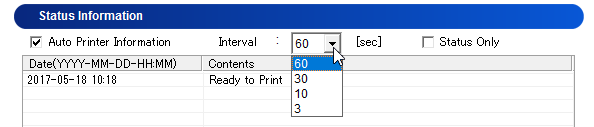

Ink level can be monitored in real-time. To use this function select the Auto Printer Information tool available in the printer status window of the ValueJet Status Monitor. When selected, this will automatically refresh the information in the intervals of 3, 10, 30 or 60 seconds.

At the beginning of each production cycle and periodically as needed it is necessary to check waste ink level.

If the printer displays a high waste ink level it is necessary to empty the tank first, and then select the Reset Waste Ink button.

Learn how to empty the tank and use the Reset Waste Ink button.

To empty the tank a container with the ability to hold at least 1.4 litres will be needed.

The Reset Waste Ink button can be only selected when physical tank has been emptied to avoid overspill into the printer.

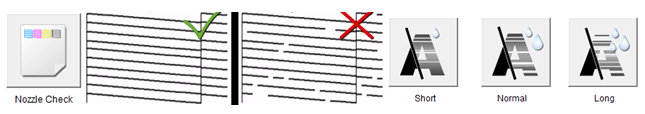

At the beginning of each production cycle and periodically as needed (between large job queues) it is necessary to perform a nozzle check.

Avoid printing when nozzles are missing and perform a short normal or long clean in accordance to the severity of any nozzle loss.

Learn how to perform a nozzle clean.

During daily operation it is recommended to perform a Little Charge as it uses considerable amount of ink and is primarily used to flush ink lines and the print head.

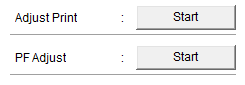

Alignment checks should be performed each time the paper/media roll is changed, the printer is moved to another location or if blurry image output is present.

The tool for alignment is located in ValueJet Status Monitor.

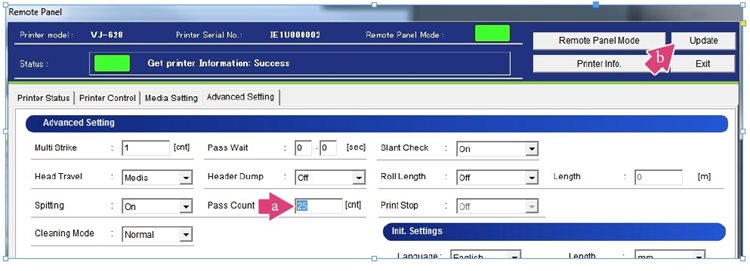

The printer will always spit into the flushing box pad before every nozzle check and before printing starts. This function may be configured manually in ValueJet Status Monitor.

With Sawgrass inks, it would be acceptable to set the spitting Pass Count to 25. This means that the print head will make 25 print passes before returning to the flushing box to spit.

If more nozzle loss is noticeable with this adjustment, the pass count can be reduced from 25 down. It is important that after selecting the pass count /a/ the change is updated /b/.

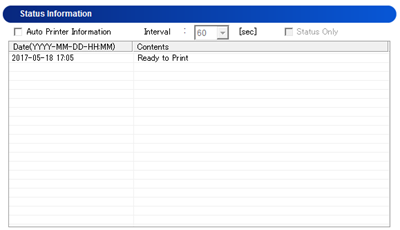

At the beginning of each production cycle and periodically as needed for any alerts or error messages or if printer begins to beep at any time it is necessary to check the Status Information Screen.

No error messages displayed should be ignored as it may cause damage to the printer. For questions on any error messages displayed, contact Sawgrass Tech Support for assistance.

Learn which consumable parts and cleaning means are needed during daily production cycles of the Virtuoso VJ628 printer.

Learn how to perform basic cleaning and maintenance actions during daily production cycles of Virtuoso VJ628 printer.